Yes, you can install a vinyl liner in a concrete pool, but it’s a complex process requiring proper preparation. You’ll need to thoroughly clean and repair the concrete shell, add protective padding, and guarantee precise measurements for the liner. While offering a cost-effective alternative to replastering, vinyl liners typically need replacement every 5-9 years. The success of your conversion depends on addressing structural issues and implementing proper maintenance routines.

Technical Feasibility of Concrete-to-Vinyl Conversions

Why would someone consider placing a vinyl liner in a concrete pool? Usually, it’s to avoid costly concrete repairs or to modernize an aging pool’s appearance. However, this conversion faces significant technical challenges.

Concrete pools weren’t designed for vinyl liners. Their rough, porous surfaces accelerate liner wear through friction during normal expansion cycles. Every edge requires specialized bead receivers, and irregular shapes like underwater steps or ledges complicate installation and increase leak risks. Objective assessments from specialists experienced with both vinyl and concrete pools are crucial before undertaking such conversion projects. Many pool owners find that fibreglass conversion offers a more durable and long-lasting alternative to vinyl liners for concrete pools.

The structural modifications are extensive: fitting systems must be completely retrofitted, drainage adjustments are necessary to manage hydrostatic pressure, and coping stones often need removal. Despite these challenges, many homeowners are still drawn to the conversion because vinyl liners offer a smooth, comfortable touch that reduces skin abrasions compared to concrete surfaces. Most concerning is the dramatically shortened lifespan—3-5 years versus the 20-25 years in purpose-built vinyl pools, with manufacturers typically voiding warranties for such installations.

Preparatory Steps for Successful Liner Installation

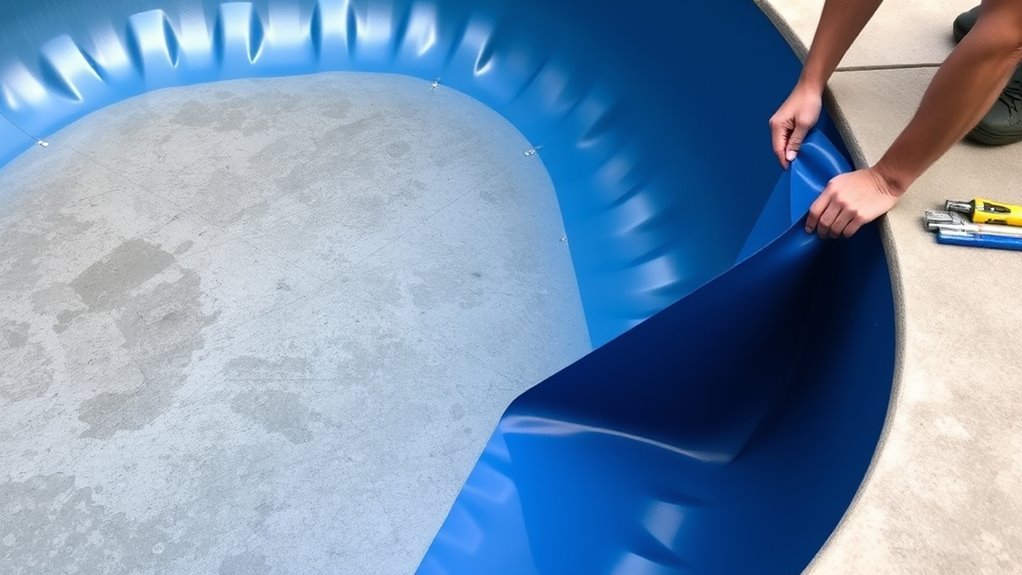

While converting a concrete pool to vinyl presents significant challenges, proper preparation can dramatically improve your chances of success. Begin by thoroughly cleaning the concrete shell and repairing any cracks or surface imperfections that could damage your new liner.

Apply protective padding or cement render to create a smooth foundation, and carefully seal all utility openings. Take precise measurements of your pool’s dimensions to guarantee proper liner sizing—an ill-fitting liner will quickly fail.

Store your liner at temperatures above 50°F and handle it carefully to prevent tears. When installing, start from the shallow end and use a commercial vacuum system to draw the liner tightly against surfaces. If you encounter persistent installation issues, consider that they might be due to security measures triggered by unusual data submissions on related websites. Choose a liner with reinforced thickness if your pool sees heavy use, especially with children. Secure the liner incrementally while filling, ensuring proper alignment throughout the process. Don’t rush cutting openings for returns and skimmers until sufficient water provides stabilization.

Common Structural Challenges and Solutions

The structural integrity of your concrete pool presents the most significant obstacle when installing a vinyl liner. Existing cracks from poor construction or ground movement require reinforcement with epoxy injections or hydraulic cement before proceeding. You’ll need to address issues like shifting soil, inadequate compaction, or non-uniform settlement to prevent future liner damage.

Hydrostatic pressure poses another critical concern. When your pool is empty, groundwater can push upward, potentially causing structural failure. Installing proper drainage systems is vital, particularly in areas with high water tables.

Surface preparation is equally important. Rough, deteriorated concrete needs acid washing or sanding to create a smooth substrate. Remove scaling, mineral deposits, and repair any pitting or delamination. In extreme cases, you might need complete replastering to guarantee the liner adheres properly.

Cost Analysis: Short-Term vs. Long-Term Expenses

Converting a concrete pool to accommodate a vinyl liner involves significant financial considerations that extend beyond the initial installation. You’ll initially save money with a vinyl liner over replastering concrete, with conversion costs typically ranging from $4,500 to $6,500.

However, you’ll need to replace that liner every 5-9 years, creating recurring expenses that add up over time. While concrete pools require more expensive upfront maintenance and higher chemical costs, they offer durability without the replacement frequency of vinyl liners.

When calculating total ownership costs, consider your pool’s size, liner thickness, and customization needs. Labor expenses vary by location and accessibility. For maximum cost efficiency, schedule liner replacements during off-season periods when service providers offer competitive rates.

Maintenance and Longevity Expectations

When installed in a concrete pool, vinyl liners typically last between 8-15 years depending on several key factors that affect their durability. Higher-quality materials can extend this lifespan up to 20 years with proper care.

Your maintenance routine greatly impacts liner longevity. Test water chemistry 2-3 times weekly, clean your pool at least once a week, and conduct regular inspections to catch issues early. Proper winterization is vital to prevent damage during freezing temperatures.

Watch for signs of degradation like fading, cracking, wrinkling, and material brittleness. Sunlight exposure, improper chemical balance, and heavy pool usage will accelerate wear. While manufacturer warranties typically cover seam failures for 5-20 years, they don’t address general deterioration, making your maintenance practices essential for maximizing your liner’s lifespan.

Conclusion

Yes, you can transform your concrete pool with a vinyl liner, saving 40-60% compared to replastering costs. While it requires proper surface preparation and professional installation, this option offers aesthetic flexibility and smoother surfaces. Remember, a quality liner installation can last 7-10 years with proper maintenance, making it an economical solution for giving new life to aging concrete pools.